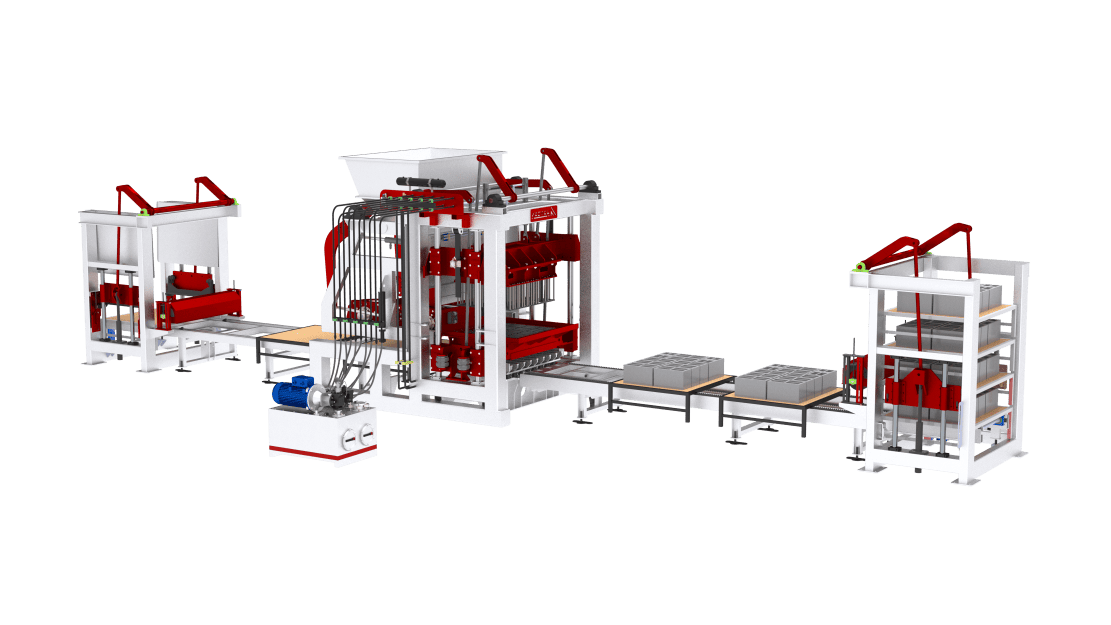

HBM10+

■ Automatic production line

■ Blocks, interlock , and curbstones

■ High productivity per hour

■ German hydraulic system

■ Siemens control panel

■ Scada computer operating system

■ Three employees to operate .

HBM-10 Plus

-The capacity is 10 stone for each cycle 200*200*400

– couple color

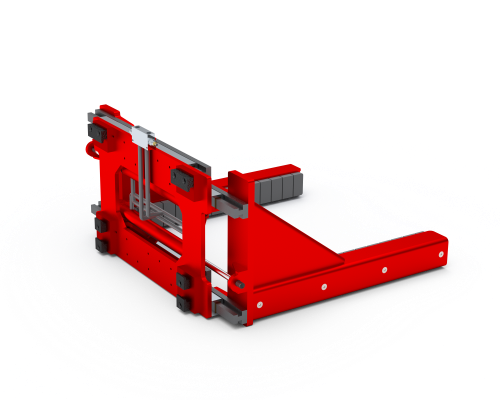

– Strong and durable steel clamp used in construction industries,.

– Strong and durable steel clamp used in construction industries,.

– It works with hydraulic pressure to lift and transport heavy concrete blocks, slabs, or other masonry materials by forklift.

– With a pallet width of 1000 mm and a rubber length of 1050 mm, it is designed to securely grip and hold the block in place during transportation, increasing safety on the work field .

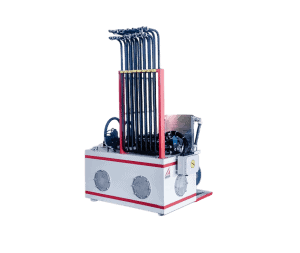

Hydraulic system for block &Interlock production line All pumps and oil system parts are made in Germany

All pumps and oil system parts are made in Germany

– System with acceleration and deceleration feature

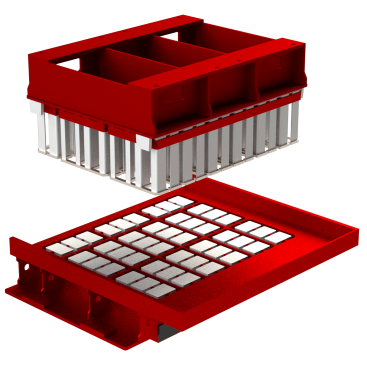

Concrete Block&interlock Mold

Different hollow block molds

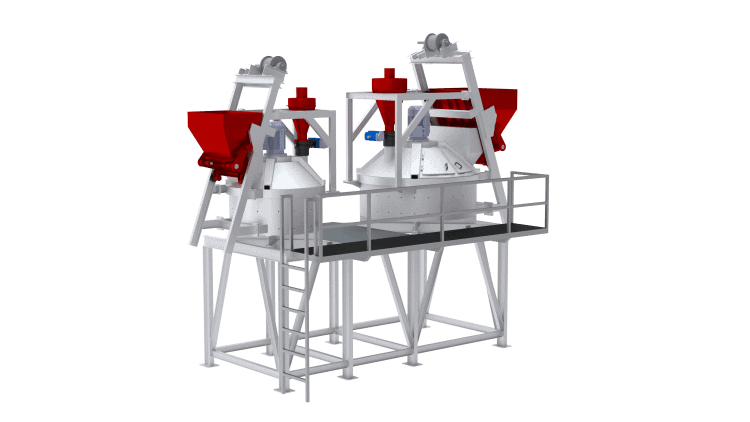

Hopper

Three-division tanks a volume of 10 m3 for each compartment

– The thickness of the sheet used is 4 mm, and the thickness of gates and

fastening area is 8 mm

– The chassis carrying tanks is H bridges 160 * 160 mm,

American size for legs, and the cutting is U bridges 100 mm

– Vibrators to Prevent the stickiness of the materials

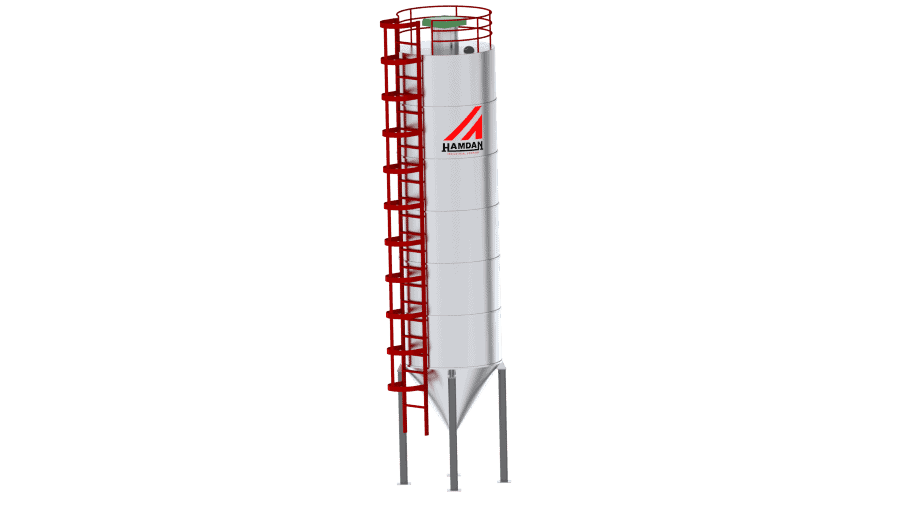

Cement Silo

Capacity of 50tons, including environmentally friendly electrical filters

Capacity of 50tons, including environmentally friendly electrical filters

and the necessary sensors

The computer and control screen& Electrical panel

Plc system operate by computer not with touching screen

– Electrical panel to operate all factory parts

ABB – Siemens –Schrneide