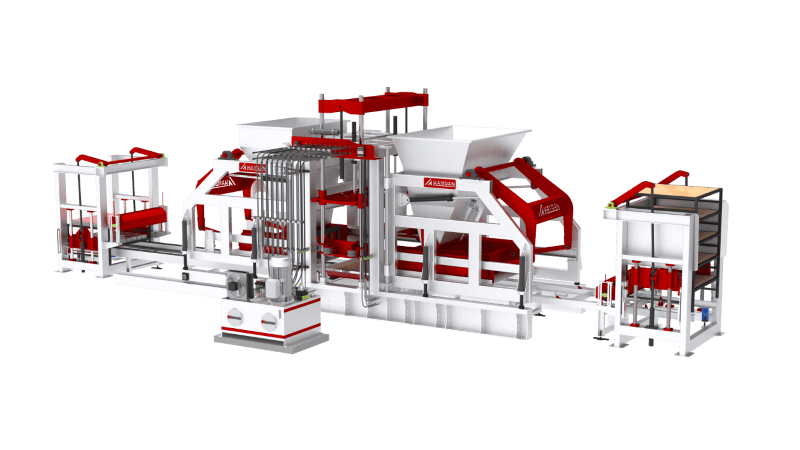

HBM 18+

■ Produce blocks, interlock and curbstones automatically with different shapes and sizes

■ Achieve high output per hour with German hydraulic system that ensures smooth and fast operation

■ Control the production line with Siemens panel and Scada computer system that allow easy monitoring and adjustment of settings

■ Only need three workers to operate the line, saving labor costs and increasing efficiency

■ The factory is characterized by an industrial safety system that complies with international conditions and specifications.

■ HBM18+ is characterized by its ability to produce all kinds of cement products.

-The capacity is 18 stone for each cycle 200*200*400

– Product high: 60 mm – 300 mm

-Palet size : 1350*1450 mm

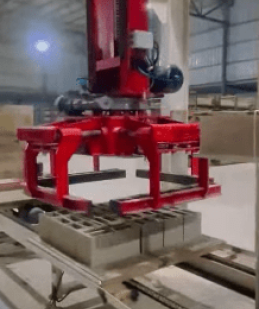

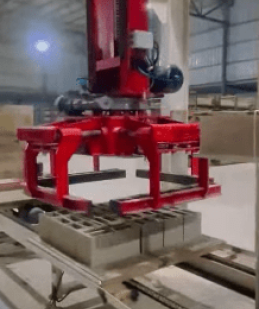

-Automatic robot to assembly products

– A Special conveyor for finished product

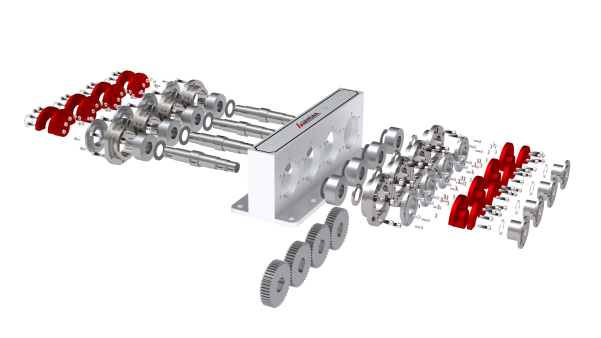

VIBRATOR

■ Engine system is adjustable to the required power/frequency cycle for the mold vibration cycle to fill the cavity uniformly and intensively vibrate the concrete to the required density.

■ Smooth cycles, low electricity consumption, optimal distribution of cement mixture and pressure on concrete.

■ Reduces the amount of cement in the concrete with equivalent mechanical force,and longer lifespan of molds.

■ Ideal vibration ratio

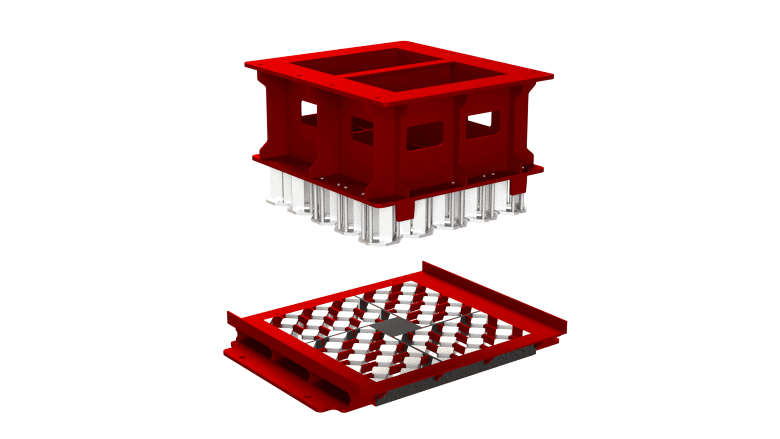

Concrete Block&interlock Mold

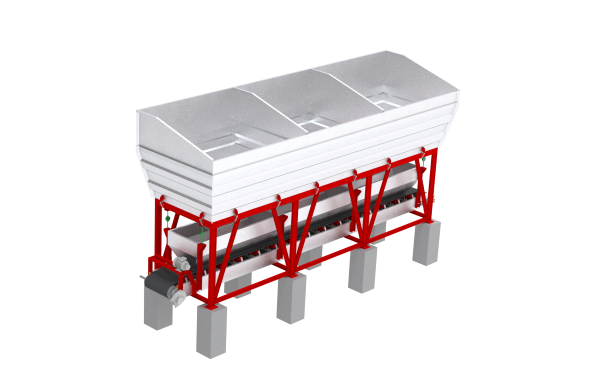

Hopper

Three-division tanks a volume of 10 m3 for each compartment

– The thickness of the sheet used is 4 mm, and the thickness of gates and

fastening area is 8 mm

– The chassis carrying tanks is bridges 160 * 160 mm,

, and the cutting is U bridges 100 mm

– Vibrators to Prevent the stickiness of the materials

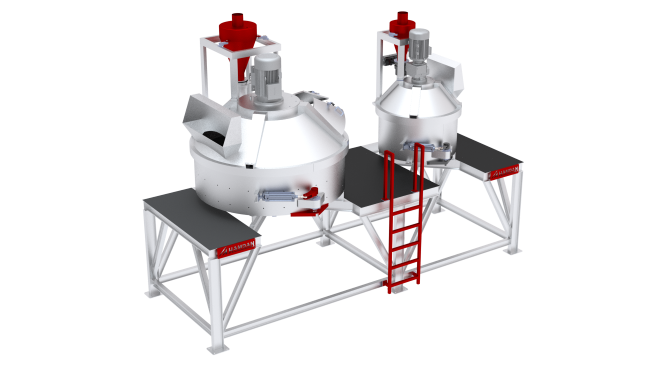

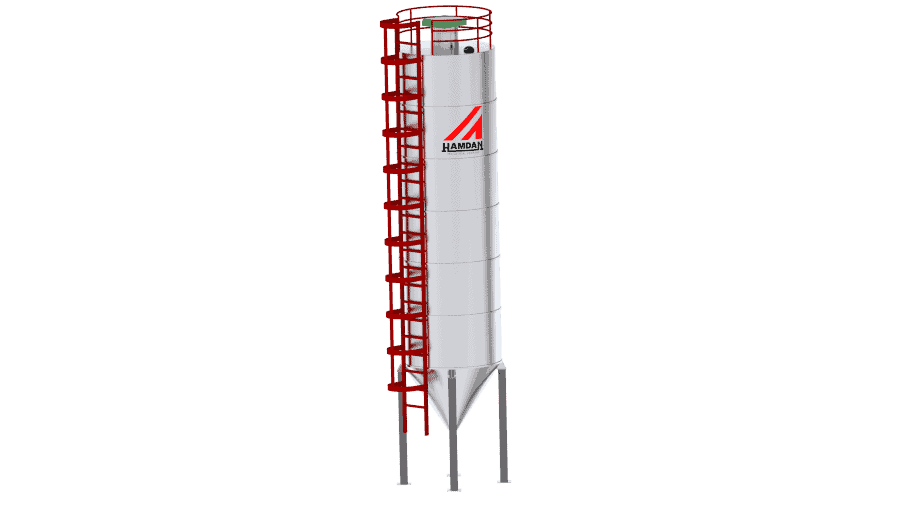

Cement Silo

Capacity of 100 tons, including environmentally friendly electrical filters

and the necessary sensors and others

The computer and control screen& Electrical panel

Plc system operate by computer not with touching screen

– Electrical panel to operate all factory parts

ABB – Siemens –Schrneide

Interlock

Production

Block

Production

01

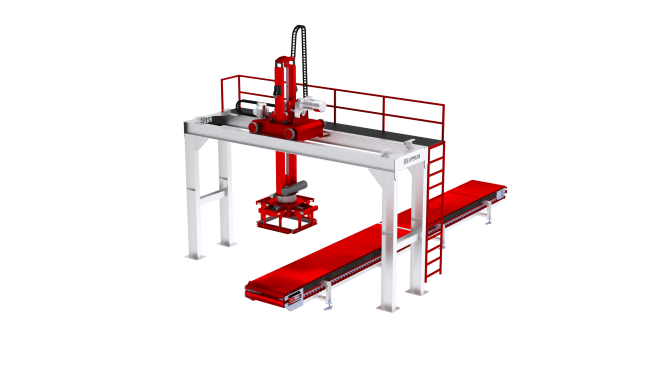

Cubing

Robot

Interlock

Production

02

cubing

robot

Block

Production

03

♦️